In today’s competitive manufacturing landscape, efficiency and precision are critical to staying ahead. Leveraging a trusted CNC Machining Service can significantly enhance your production workflow, improve product quality, and reduce lead times. Whether you’re in aerospace, automotive, medical, or consumer electronics, the right CNC partner ensures consistency and scalability across all phases of production.

This article explores the core benefits of integrating a reliable CNC Machining Service into your operations. From accelerating design to delivery, enhancing accuracy, scaling production, ensuring quality, and maintaining cost-efficiency, you’ll learn why working with seasoned professionals in CNC machining is vital to operational success.

Accelerate Design-to-Production Time

Speed is everything in modern manufacturing. A reliable CNC Machining Service helps businesses move from the conceptual design phase to physical production swiftly and smoothly. Advanced CNC equipment can quickly translate digital CAD files into precision-machined components, reducing the need for manual setup and minimizing time-consuming iterations. The digital workflow enables rapid prototyping, allowing engineers to test and refine designs faster than traditional manufacturing methods.

Moreover, trusted providers often offer expert guidance during the design-for-manufacturing (DFM) phase. By collaborating early with a CNC Machining Service, manufacturers can optimize designs to be more production-friendly. This streamlining not only decreases turnaround times but also limits costly redesigns and delays. Whether launching a new product or scaling up production, reducing the time between idea and implementation is a game-changer.

Enhance Accuracy and Repeatability

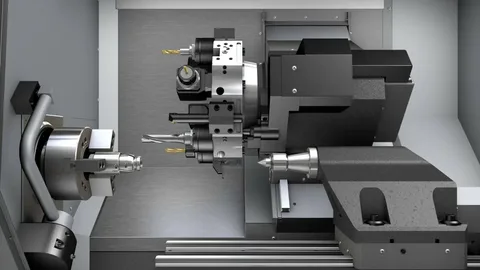

One of the greatest advantages of partnering with a professional CNC Machining Service is the unparalleled precision they bring to the table. CNC (Computer Numerical Control) machines are capable of executing complex cuts and shapes with tolerances as tight as ±0.001 inches. This level of accuracy is essential in industries where even the slightest deviation can result in product failure, such as in medical device or aerospace component manufacturing.

In addition to accuracy, CNC machining ensures repeatability. Once a program is created and perfected, it can be reused to produce identical parts over and over again. This ensures consistency in production batches, which is particularly important for maintaining quality standards and meeting regulatory requirements. Reliable CNC Machining Services invest in modern equipment and rigorous process controls to ensure every part meets exact specifications.

Scale Production Without Sacrificing Quality

Scalability is crucial for businesses looking to grow, and a dependable CNC Machining Service allows manufacturers to scale production without compromising on quality. Whether you need a small run of specialized parts or mass production of standardized components, CNC machining can be tailored to meet diverse production needs. With minimal retooling and automated processes, switching from prototype to full-scale production is seamless.

Furthermore, trusted CNC providers use sophisticated software and production scheduling systems to manage larger orders efficiently. Their ability to scale ensures that lead times remain consistent even as order volumes grow. This flexibility is especially beneficial for companies that experience seasonal demand fluctuations or are looking to introduce new products without disrupting their existing manufacturing workflow.

Ensure Product Quality and Compliance

A reputable CNC Machining Service goes beyond just cutting and shaping materials—it ensures each part meets stringent quality and regulatory standards. Quality control measures such as in-process inspections, CMM (Coordinate Measuring Machine) checks, and final audits are embedded in the production workflow. These steps help identify deviations early, reducing the risk of defective products reaching the customer.

In regulated industries, compliance is not optional. Certified CNC Machining Services typically hold ISO 9001 or other relevant certifications that indicate adherence to global quality management standards. Additionally, they maintain detailed documentation and traceability for every part produced, which is crucial for industries like defense, medical, and aviation. This focus on quality assurance not only protects your brand reputation but also ensures that your products are always reliable and compliant.

Reduce Operational Costs and Improve ROI

Working with a professional CNC Machining Service can also deliver considerable cost savings. While the upfront investment may seem higher compared to manual or less automated services, the long-term return on investment is significant. CNC machines reduce the need for manual labor, lower scrap rates, and minimize rework costs—all of which contribute to a more cost-effective production line.

Moreover, outsourcing to a CNC Machining Service reduces the need to invest in expensive equipment, tooling, and specialized labor. This allows manufacturers to allocate resources more efficiently and focus on core business activities such as product development and customer service. By improving production efficiency and reducing waste, CNC machining delivers a higher yield and better profit margins over time.

Conclusion

Incorporating a trusted CNC Machining Service into your production strategy is more than a smart choice—it’s a strategic advantage. From faster turnaround times to exceptional accuracy, scalability, stringent quality control, and significant cost efficiencies, the benefits are comprehensive and compelling. Businesses that leverage the capabilities of modern CNC machining not only boost their workflow but also position themselves for sustained success in an increasingly demanding market.

When choosing a CNC partner, prioritize experience, certifications, and a commitment to precision and customer service. With the right CNC Machining Service by your side, you’ll be empowered to innovate, scale, and deliver with confidence—no matter your industry or production goals.